Electromagnetic interference refers to the unintentional emission of radio frequency energy created by an electrical or electronic device (generally called source). This interference or noise may have negative effects on essential communications and the performance of other electrical products (victims or receptors). Devices such as radios, TVs, electrical lighting or vehicles could propagate intolerable electromagnetic disturbances through the environment.

We probably don’t realise in our everyday life that artificial light has a bigger impact in our environment than the simple fact of illuminating spaces by throwing luminous flux.

Nowadays the increasing presence of electronic equipment to control/operate luminaires makes it a more delicate matter. I am talking about electromagnetic interference of electrical lighting products.

Electromagnetic interference refers to the unintentional emission of radiofrequency energy created by an electrical or electronic device (generally called source). This interference or noise may have negative effects on essential communications and the performance of other electrical products (victims or receptors). Devices such as radios, TVs, electrical lighting or vehicles could propagate intolerable electromagnetic disturbances through the environment.

Electromagnetic compatibility (EMC) is the ability of any equipment or system to operate satisfactorily in its electromagnetic environment without interfering or detriment to other devices.

Electromagnetic interference (EMI) can be:

- Conducted: by means of currents induced in the electrical conductors along the electrical network and transferred to other equipment connected to it.

- Radiated: propagated through the space, without physical contact of electrical conductors.

Electromagnetic interference in lighting equipment

The vast majority of electrical lighting products today contain electronic control gear: these are transformers, power supplies, electronic ballasts or drivers (sometimes integral, sometimes remote), connected to low voltage mains electricity. These devices are present in LED technology, fluorescent, halogen and even HID lighting. AC current in an electronic circuit produce magnetic fields that may induce electromagnetic interference in other devices around it.

Electronic control gear operates at very high frequencies (much higher than 50 - 60 Hz of mains supply) in order to increase the efficiency of the electrical conversion, reduce heat dissipation and minimise their size and weight. The downside is that they generally include switched-mode circuits that switch the forward current on and off to produce the high frequencies. If not properly filtered, it results in the emission of radiofrequency interference, i.e. EMI.

Even the cheapest low-power LED lamps can become highly troublesome if the emission of electromagnetic noise is not properly mitigated. This is a common EMC issue In LED lighting: inexpensive light sources, the preferred choice for domestic use by the average consumer, that once installed interfere with other electronic devices at home, especially audio-visual equipment: television, radio, phone communications, etc.

Thus, the potential electromagnetic interference caused by lighting products does not come from the light sources but from the circuits and control gear that generates the power to operate.

ACMA and the required compliance with EMC standards

The Australian Communications and Media Authority (ACMA) is the government agency that regulates telecommunications, broadcasting, radiocommunications and the internet in Australia. It also regulates the electromagnetic compatibility (EMC) of electrical and electronic devices supplied to the Australian market, under the Radiocommunications Act 1992.

ACMA implemented the EMC Regulatory Arrangement which imposes compliance with applicable EMC standards for those devices. To do so, ACMA classifies all electrical and electronic devices supplied in Australia into 3 compliance levels:

- level one or low-risk devices,

- level two or medium-risk devices, and

- level three or high-risk devices.

The higher the compliance level, the more requirements and documentation must be kept by the suppliers of the devices (whether they are manufacturers or importers).

Most lighting products fall within the scope of level two, medium risk. ACMA enforces suppliers of medium-risk devices to meet the requirements of their applicable EMC standard, keep evidence of compliance documentation and labelling the products accordingly. Compliance against the applicable EMC standard is demonstrated by means of a test report. In particular for electrical lighting equipment the mandatory standard is: AS/NZS CISPR 15.

Incandescent lights and battery-powered lighting however, fall within the scope of low-risk devices and their suppliers are not required to hold a test report conforming to any applicable standard.

CISPR is a French acronym for International Special Committee on Radio Interference, the commission that sets international standards for electromagnetic interference. This Australian and New Zealand Standard (AS/NZS) aim to ensure the electromagnetic compatibility of the lighting equipment. It establishes the limits and methods of measurement of radiofrequency emissions, conducted and radiated, for lighting products. But ACMA also recognises compliance to equivalent international standards CISPR 15 and EN 55015.

EMC tests of lighting products: measurements

EMC test to comply with CISPR 15 is required for all medium-risk (level 2) electrical lighting equipment and can be carried out in-house (by the manufacturer or supplier) or by an external laboratory.

Despite some lighting manufacturers have their own EMC laboratories, these tests are generally conducted in external laboratories where they have the expertise and testing equipment required: spectrum analysers (receiver equipment), Line Impedance Stabilization Network (LISN), Coupling-decoupling Networks (CDN) or loop antennas, among others.

The test comply with CISPR 15 standard can be divided into 2 sections: conducted and radiated disturbance.

Disturbance voltage refers to conducted radiofrequency emission and can be defined as the undesired voltage (noise) induced by any device or equipment connected to an electrical system. This disturbance is generated by switching transistors or harmonic resonances (present in electronic transformers and drivers for lighting gear) and if not adequately mitigated, can induce currents in the physical wiring of the network, interfering into other devices.

The disturbance voltage is tested with a LISN instrument on:

- mains terminals: input electrical connection of the lighting product

- load terminals: lines connecting the control gear with the light source/s, and

- control terminals (if existing/any): lines connecting the luminaire to any type of control system that regulates the light output (e.g. dimming, DALI control)

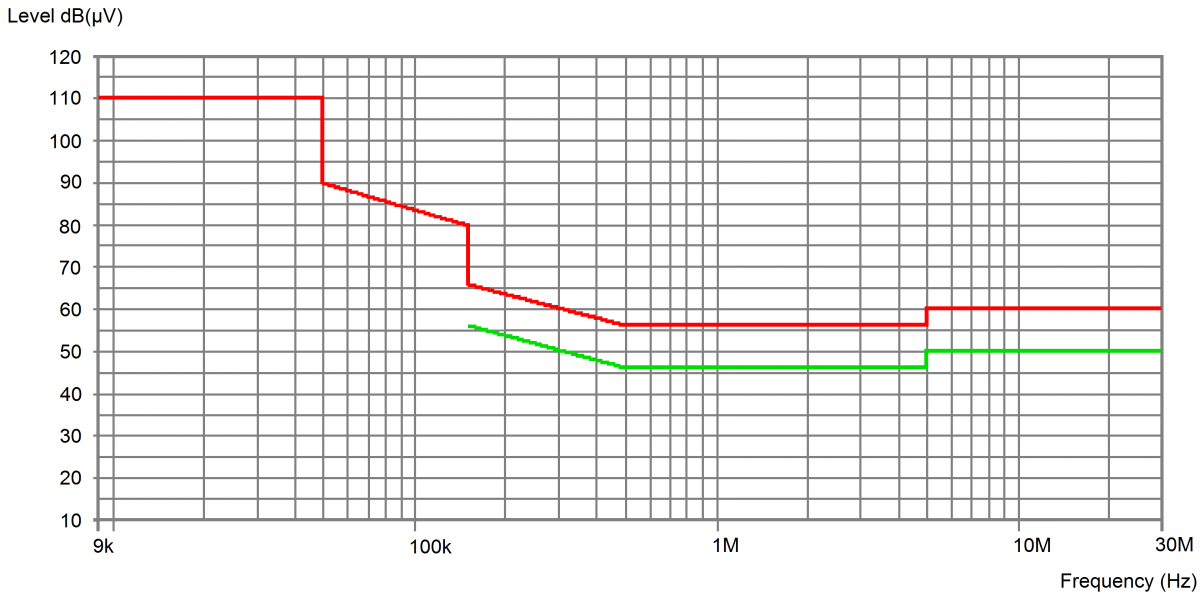

Results are generally displayed in graphs. The frequency range is represented in logarithmic scale on the horizontal axis. The disturbance voltage is scanned throughout the frequency spectrum and measured in decibel (dB), relative to a reference of 1 µV. The values utilised are based on quasi-peak and average detection. Quasi-peak scanning weighs the disturbance signals depending on its repetition rate at different frequencies.

Figure 1 represents the maximum values of disturbance voltage at mains terminals: the red line represents quasi-peak limits and the green line average limits:

Figure 1. Graph representing the limits of disturbance voltage at mains terminals

Therefore any device analysed under this test must emit values of radio disturbance below those limits in order to comply with CISPR 15 standard.

Radiated disturbance means electromagnetic disturbance transmitted through space in the form of electromagnetic waves. A large portion of the disturbance energy is radiated by the electrical conductors connected to the equipment. This radiation depends on the resonance characteristics of the cables, and resonance is a function of the frequency.

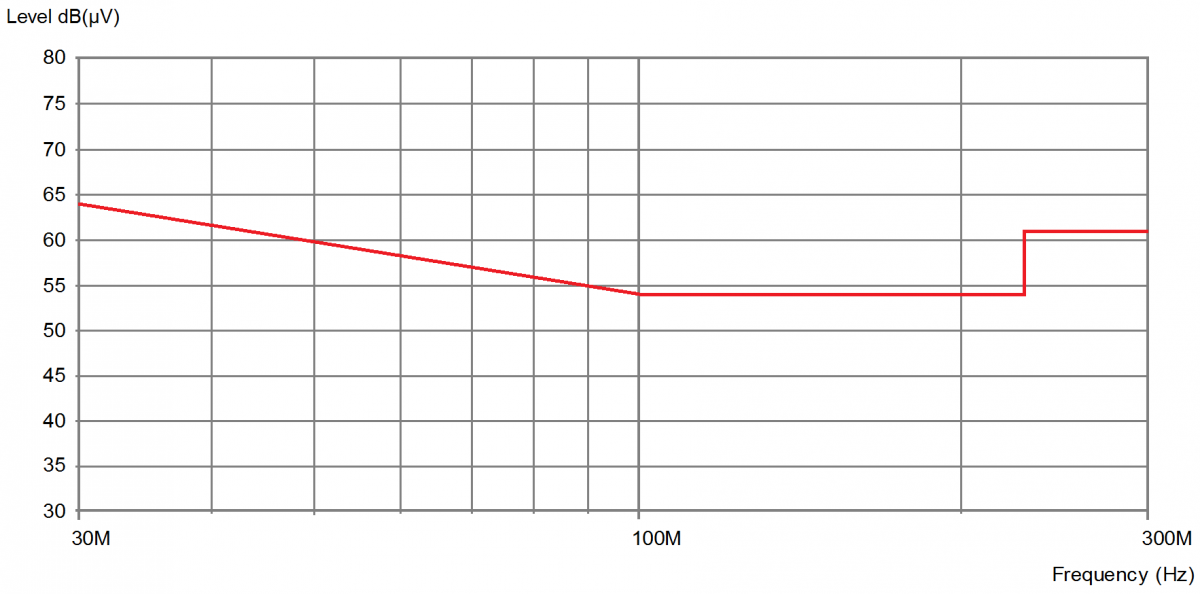

Compliance to the radiated disturbance limits for lighting equipment is tested at 2 different frequency ranges and with different equipment:

- From 9 kHz to 30 MHz where a loop antenna measures the level of current in dB (referred to 1 µA)

- From 30 to 300 MHz using a coupling-decoupling network

Figure 2. Graph representing the limits of radiated disturbance [dB(µV)] in the 30-300 MHz frequency band

Not all the mentioned tests are applicable to all different technologies that exist in lighting; reason why they must be conducted by laboratory technical personnel capable to interpret the requirements of CISPR 15 standard.

The results of the tests shall be presented in a test report, stating that the lighting product passed or failed the compliance to CISPR 15 standard. The responsible supplier must keep the report together with the relevant compliance documentation of that product.

In case of a device that fails the test, it (the lighting product) shall be modified and corrected to ensure the levels of EM disturbance remain below the limits. No lighting product should not be supplied into the market until a test report specifies ‘pass’ and complies with the standard.

The procedures described in CISPR 15 analyse and measure something invisible, sometimes ‘irrelevant’ and overlooked by the partakers of lighting industry. However EMC plays an important role in the performance of lighting products and its environment, and it requires: well-designed electronic equipment, adequate wiring and EMI filters to reduce the emission of noise.

As mentioned before in the example of the LED lamp, the majority of issues with EMC in lighting products come from economising with components for the final product and not considering the necessary testing. And these issues are especially noticeable today with such strong competition in LED lighting products and the development of smart home-automation systems.

The compliance testing can make the difference between two simple 7W LED lightbulbs available in any store with a price difference of just a couple of dollars. But it will make end users confident that the products purchased will not cause any trouble on equipment and communications around them.

Have something to say on this? Share your views in the comments section below.