Published: 2 March 2015

Category: Technical Articles

Believe it or not the term “termination” is not defined in the Wiring Rules. The dictionary defines termination as “bring to an end”, or to “put an end to”, so one could argue that we are going to bring the cable to an end, to put an end to it being a cable, or even just end its employment.

Fortunately, the Wiring Rules are clear when a term is used within the Wiring Rules that is not specifically defined. In that situation, the commonly understood meaning shall apply as used in the electrical field.

We, in the electrical industry, have been guilty for years of using incorrect terminology, and this is just another case of such. The correct terminology is connection, and for our trade “electrical is connections”. This is defined under clause 3.7 in AS/NZS3000: 2007 as the connection between conductors and other electrical equipment, or as per the dictionary, a joint between two electrical conductors.

Now that we have established what we are on about, let’s look at the requirements to complete a compliant electrical connection.

Back in “the good old days” when the Wiring Rules were more prescriptive, there were a lot of rules in relation to connections of conductors to electrical equipment.

These included but were not limited to:

- No more than four conductors in a fixed tunnel terminal at the rear of an electrical accessory.

- All earthing conductors 2.5mm2 or smaller shall be twisted together prior to termination.

- All earthing conductors up to and including 16mm2 shall be terminated by soldering.

These current Wiring Rules are not as prescriptive as they were, but no less, they in general still exist. The fundamental principle must be achieved. The fundamental principle is the provision of electrical continuity, thus ensuring that the connection is not less in continuity than the original conductors, along with an appropriate level of insulation and adequate mechanical strength.

It is not my intention to repeat the Wiring Rules as you can go and read them at your leisure, however, I will point out some of the more interesting rules and also some of those that appear to be regularly breached.

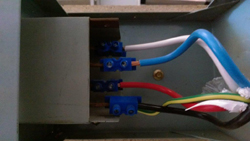

There is no restriction on the number of conductors being connected together. All that is required is that you take into account the number of conductors to be joined and select an appropriate method of connection for that number of conductors being joined, to ensure that the fundamental principle is complied with.

One connection requirement that I constantly see breached is in relation to the retention of stranded conductors. Many electricians simply strip the outer sheath and the insulation off the conductor, then push it into a tunnel type connector.

They do not consider that the screw pushes some of the strands to the side and that only 3-4 strands are retained under the screw.

This does not meet the requirement of a proper connection.

However if they considered twisting the conductors together, prior to connecting into the tunnel type connector, this should of itself ensure a proper connection.

Or, better still the use of bootlaces or ferrules that are crimped onto the conductor prior to connecting the conductor into the tunnel terminal provides a better option.

Following on from this example is the cutting down of crimp lugs, redrilling of the crimp lug or connecting a crimp lug to a terminal or bar that is smaller in surface area to that of the crimp lug.

Remember that one of the fundamental principles is to ensure that the conductivity and current carrying capacity of the joint or connection is not less than that of the conductor.

Therefore the modification of any crimp lug for any reason renders the connection as non-compliant.

The Wiring Rules require conductors joined or terminated by means of a crimp connection to be securely retained within a suitable crimping device. This connection shall be made using a tool designed for the purpose and techniques specified by the manufacturer. Please note that this does not include pliers.

There is no longer a requirement to use two screws to connect an earth conductor in either a fixed or floating connection, providing that the earth conductor is connected into a tunnel type connection with one screw with an outside diameter not less than 80% of the tunnel diameter into which the earthing conductor is to be installed.

Unsupported conductors that create stress on conductor terminals is another example that comes to mind. All cables regardless of their size, from 1mm2 up to 500mm2, require supporting to remove the stress of the connection.

Distances of large cables in excess of 100mm between the cable support and the termination point may cause undue stress on the connection. Remember to always support cables prior to the termination point.

And finally, with the preparation of conductors it should be remembered that the insulation on a conductor shall not be removed any further than is necessary to make the connection.

And when the connection is between insulated conductors, the connection shall be insulated to provide a degree of insulation not inferior to that of the original conductors being joined.

Any damaged insulation shall be reinstated and remember the Energy Safe Victoria ruling that insulating tape is only acceptable if contained within an enclosure.

The acceptable enclosures are switchboards and J Boxes or similar.