Published: 30 September 2014

Category: Manufacturer News

System integrator Tianjin Qihaixin has managed to reduce panel sizes and installation costs thanks to the many built-in features of ABB’s Softstarters.

Tianjin Qihaixin Integrates efficiency in heavy-duty crushers

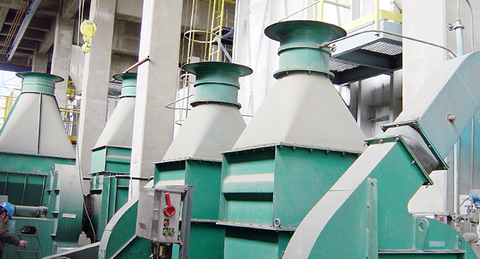

China based Tianjin Qihaixin Electric Company is a system integrator targeting the water and cement segments. For a recent project, Tianjin Qihaixin delivered equipment for a cement project in the Yunnan province of china. Crusers, roots blowers and conveyor belts united made up a product capacity of over 5 tons per day. And it was crucial that the equipment had sufficient motor control equipment. In order to

The challenge

When starting a crusher, root blower or conveyor belt – all considered heavy loads – the starting phase of the equipment is the most crucial part. Tianjin Qihaixin had experienced problems starting the equipment before, requiring them to invest in separate up-scaled equipment just to deal with the heavy loads. Furthermore, as Tianjin Qihaixin used conventional softstarters, external bypass contactors and thermal overload relays had to be used.

The ABB solution

By switching to ABB’s softstarters, benefits were clear and immediate. Featuring built-in bypass contactors and thermal overload relays, Tianjin Qihaixin can reduce its equipment size – saving them both time in installation and money from having fewer products to order and administrate. Furthermore, ABB’s softstarters can be selected to handle heavy-loads, meaning Tianjin Qihaixin could choose the same equipment regardless of the loads’ characteristics. As a direct result from choosing the ABB softstarters, Tianjin Qihaixin estimates reducing both panel costs and space with an impressing 20 percent.

To find more information on ABB Softstarters including the new PSTX Softstarter click here